Technically all thread rod made from a36 steel should be ordered to a fastener specification such as a307 grade a a307 grade b f1554 grade 36 or sae j429 grade 2.

1 2 inch threaded rod tensile strength.

Typically used by the plumbing and contracting trades.

Used in maintenance departments in various applications.

Astm f593 meets standards for stainless steel bolts hex cap screws and studs of diameters 1 4 to 1 1 2.

The superstrut threaded electrical support rod is designed to suspend superstrut metal framing channel from ceilings.

1 2 13 0 54 1130 1010 5 8.

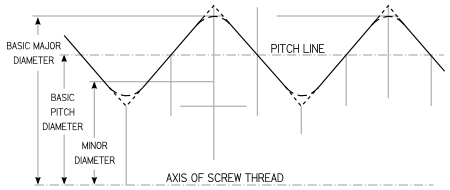

Proof loads and tensile strengths are computed by multiplying the proof load stresses and tensile strengths stresses by the stress area of the thread.

1 the maximum loads in the table above are based on allowable tensile stress of 12 kpsi reduced by 25 to 9 kpsi allowable stress.

Tensile strength yield strength sku.

1 kg 9 81 n.

Refer to the mechanical properties chart for the subtle strength differences within each grade.

18 8 stainless steel threaded rods 18 8 stainless steel threaded rods have good chemical resistance.

A b and c which denote tensile strength configu ration and application.

About half the strength of medium strength steel threaded rods use them for light duty hanging mounting and fastening.

08 22 19 page 1 of 7.

Long with a 1 2 in.

As 0 7854 d 0 9743 n squared where d equals nominal diameter in in.

And n equals thread per inch.

There are three grades.

Each piece is 10 ft.

Din 975 meets german standards for threaded rods.

1 2 13 x 10 ft astm a307 gr a zinc plated low carbon steel threaded rod.

Imperial inch tensile strength.

1 2 10 6 ft plain 60000 psi 47549 ea.

Mass and weight the difference.

It also covers socket head cap screws 1 1 2 and smaller.

Threaded rod tds version date.

However some companies stock all thread rod manufactured from a36 steel and can certify it as such upon.

Threaded rod plain zinc galvanized stainless steel doc.

Threaded rods proof load capacities in metric units.

Note that hangers supporting steam water air or gas piping systems should be able to carry the weight of piping insulation valves and other equipment.

The rod features an electro galvanized finish and has a 3 500 lb.

The appropriate fastener specification will depend on the application.

The most economical and most common form of threaded rod.